Projects

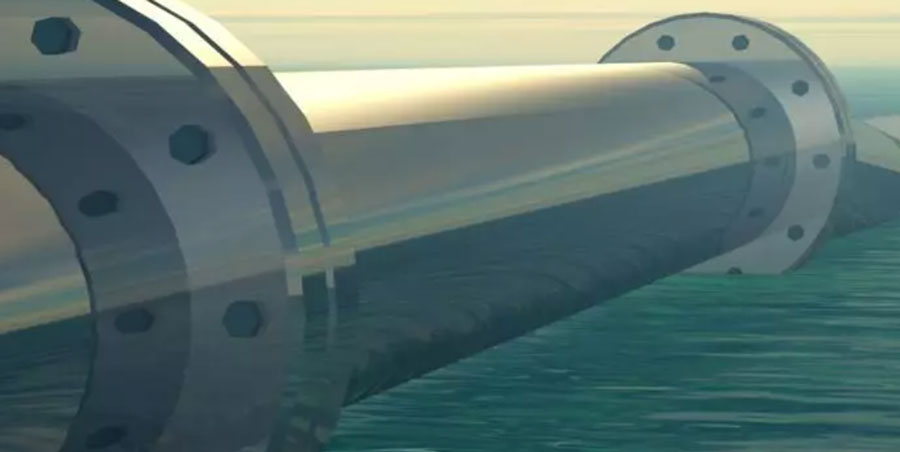

Hydrogen-induced stress cracking of duplex stainless steels

I worked with a team at ABC University to develop an in-depth insight into the cracking behaviour of DSSs exposed to hydrogen and provide new, quantitative methods for assessing and designing against HISC, as well as providing data to enable the production of more reliable assets.

Novel multi-zone self-heated out-of-autoclave composite tool

Assisted in the development of a multi-zone self-heating composite manufacturing tool is developed to manufacture high quality, stiffened lower wing panels parts while reducing cost and energy consumption compared with autoclave processes. The heating elements are embedded within a robust tool while being controlled by a thermal management system.

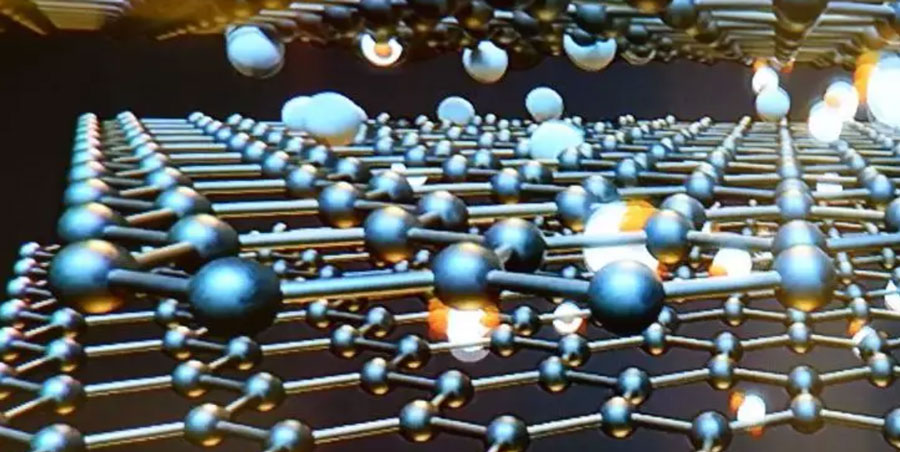

Graphene sensor for defect detection in composite materials

Assisted faculty in researching graphene in order to build a customised substrate to achieve enhanced defect sensing and predictive maintenance with increased sensitivity. The sensor will be embedded with the composite during manufacturing or applied to the surface of the component and will have high flexibility properties. A unique feature of the novel technology is that graphene will serve as the sensing element and act as the gate through with the electric current passes. Being a permanently installed sensor either embedded as part of the composite at manufacture or attached to the surface for existing components, condition monitoring will therefore be continuous and in real-time.